Braid packings have different uses in industry.

Main uses are:

- Static sealing: covers, closings, furnace doors ect.

- Rod sealing: valves

- Dynamic shaft sealing: piston pumps

- Rotary shaft sealing: centrifugal pumps, agitators, blendors ect.

Main materials to produce braid packings are:

- GRAPHITE FIBRES: suitable in applications where it is necessary a very good chemical resistance.

- VEGETABLE FIBRES like COTTON/HEMP: particularly recommended in applications where it is necessary a strong wear resistance and resistance to hot water.

- SYNTHETICS FIBRES like PTFE/ACRYLIC/ARAMIDIC/PAN/POLYESTER: very good resistance to chemical and corrosive agents.

- INSULATING FIBRES like GLASS/CERAMIC: very good for thermal insulation.

- METALS like STAINLESS STEEL/INCONEL/COPPER: are used as reinforcement for braids in order to increase mechanical resistance to high pressure and temperature.

- BONDING AGENTS & LUBRICANTS like OIL/MINERALS/SINTETIC GRASES/GRAPGITE IN DISPERSION/PTFE/MOLYBDENUS BISOLPHIDE Mos2: lubricants are a fundamental part in the packing component, they must be resistant to fluids with which they are in contact and they must not corrode metals. They gives self-lubricating and anti-friction properties (with graphite dispersion/Mos2), chemical and corrosive resistance (with PTFE).

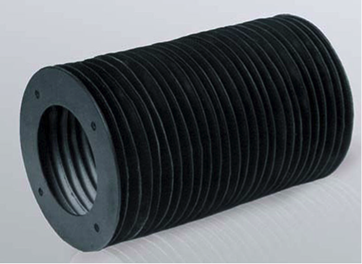

Bellows are used to protect rods or guides systems against durty and dust. Can be manufactured in different materials like rubber fabric, aluminazed glass fibres, aramidic fibres, lather and rubber.

® Trade s.a.s di Galla Andrea & C. - Via Lombardia 46, Sarnico (BG) - P.IVA 02021700162